When threads tangle under the needle plate, the machine stops, blocks the fabric feed, or damages the fabric. The cause is usually not the machine itself, but rather the thread tension, threading, or needle position.

What is a thread salad?

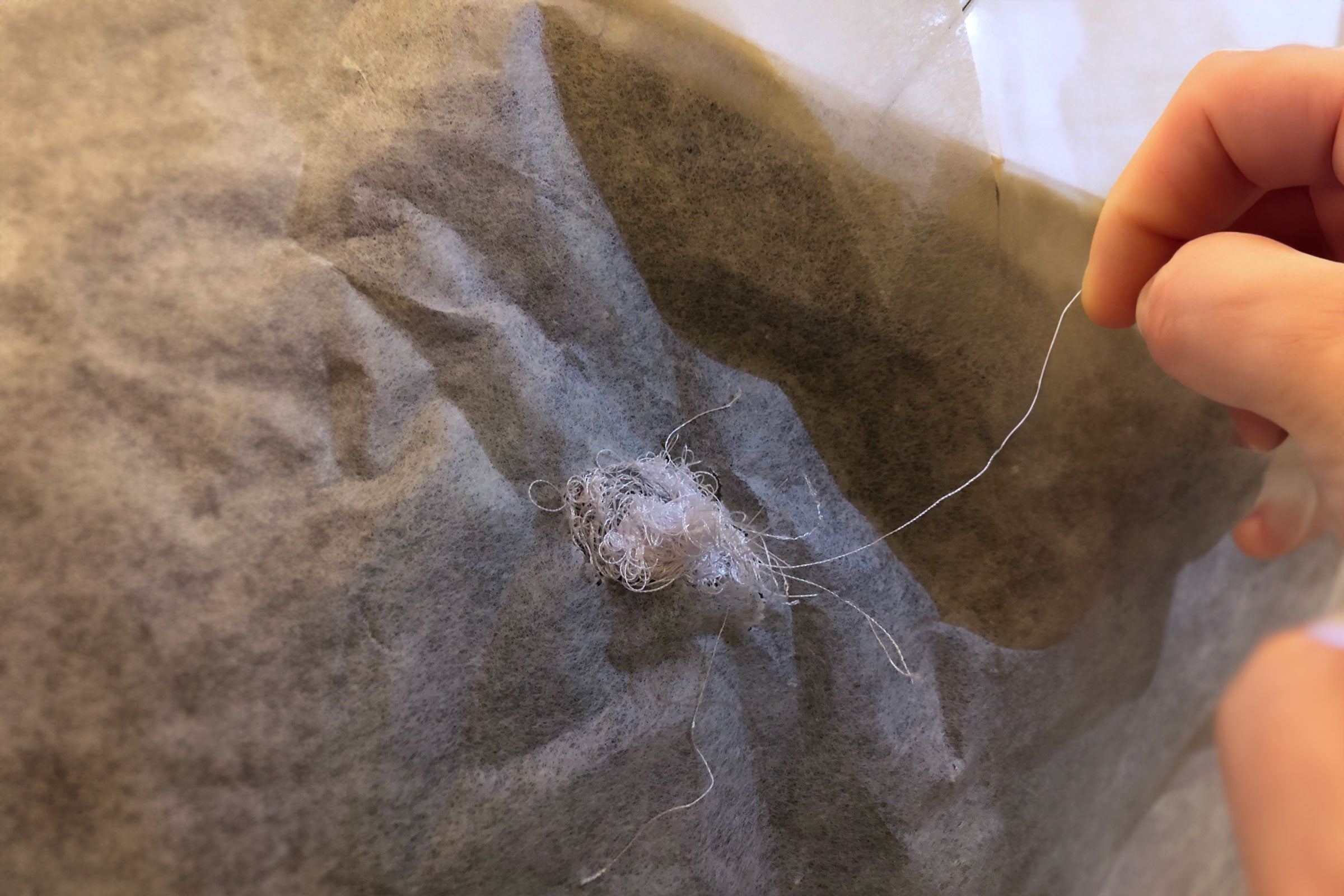

A "thread salad" refers to an uncontrolled accumulation of bobbin and/or upper thread under the needle plate. This can result in loops, knots, or entire balls of thread that wrap around the bobbin case or hook.

Common causes of thread salad

1. Upper thread not threaded correctly

One of the most common causes is that the thread path isn't fully utilized, resulting in a lack of tension for clean stitches.

2. Sewing machine was threaded with open presser foot

The thread tension discs only open when the presser foot is raised. Threading the upper thread with the foot lowered will result in insufficient tension.

3. Incorrect or damaged needle

A bent, blunt or incorrectly inserted needle will result in skipped stitches and loops.

4. Thread tension incorrectly set

If the upper thread tension is too low or the lower thread is too tight, loose thread loops will form in the hook area.

5. Bobbin inserted incorrectly

An incorrectly inserted bobbin will result in incorrect thread pick-up by the hook.

6. Contaminated gripper area

Lint, yarn remnants or inadequate care can hinder the thread play and cause malfunctions.

Step-by-step: How to fix a thread salad

-

Switch off the machine immediately

→ Prevents damage to the engine or needle breakage -

Remove presser foot and needle

→ Create more space for error analysis -

Carefully loosen the fabric

→ Never tear – rather cut threads all around -

Unscrew the needle plate

→ Expose thread nests under the plate -

Remove threads and residues completely

→ Work with tweezers or brush -

Check and clean grippers

→ Lightly oil if necessary (only according to instructions) -

Rethread the upper and lower threads

→ Be sure to raise the presser foot -

Carry out a test stitch on the remaining piece

→ Check if the problem occurs again

How can you avoid string salad?

- Always thread the upper thread with the presser foot raised

- Clean the machine regularly (hook area & bobbin case)

- Use only suitable, intact needles

- Set even thread tension to suit the fabric

- Pay attention to yarn and bobbin quality

Summary

A tangled thread under the needle plate is usually caused by incorrect threading or incorrect tension. With systematic analysis and regular maintenance, the problem can be quickly resolved—and permanently avoided.

Split:

Embroidery machine does not stop

Needle plate is not recognized