Modern embroidery machines automatically detect whether the correct needle plate is inserted. This prevents damage and protects against skipped stitches. If the message "Needle plate not recognized" appears, there is usually a mechanical fault in the sensor connection – often invisible, but easily remedied.

How does the embroidery machine recognize the stitch plate?

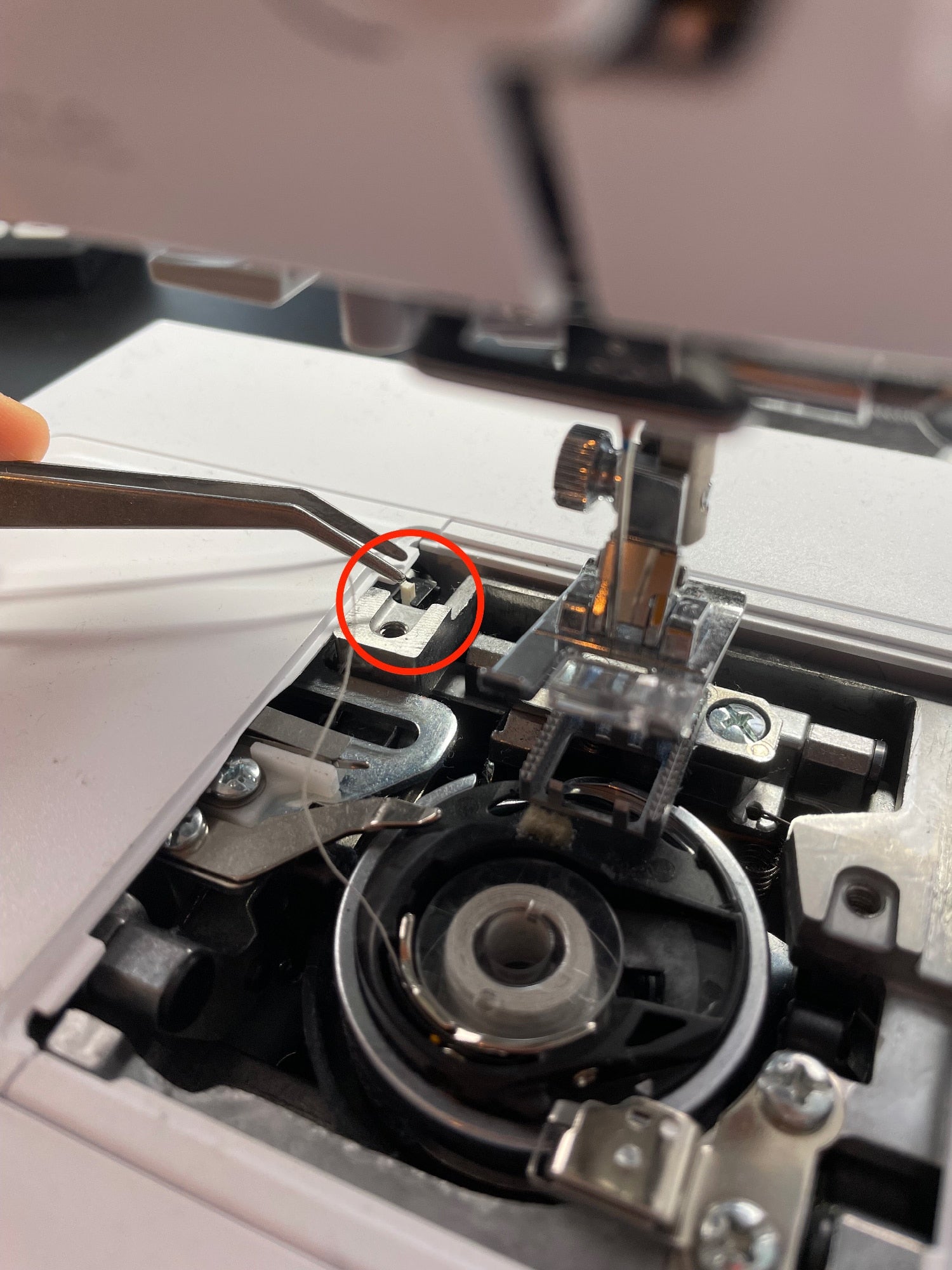

Detection is not done electronically via the needle plate itself, but via a small plastic piece (a "nupsi") attached to the underside of the original needle plate. When inserted, this piece presses against an internal microswitch or sensor pin in the machine.

Only through this physical contact does the embroidery machine recognize that the stitch plate is correctly mounted. Without this impulse, the machine blocks the embroidery process for safety reasons.

Causes: Why is the needle plate not recognized?

1. Needle plate not correctly engaged

A slightly displaced or not fully engaged needle plate prevents contact with the sensor.

2. Plastic nub is missing or damaged

If the needle plate has been subsequently cleaned or modified, the sensor trigger on the underside is often missing.

3. Foreign needle plate used without sensor nubs

Non-original or modified needle plates often do not have a sensor activator.

4. Sensor mechanism blocked

Dust, thread residue or a jammed sensor can prevent the switch from triggering.

5. Error after software update

In rare cases, an update may result in incorrect interpretation of sensor values. Calibration or a reboot may help.

How to fix the problem step by step

-

Switch off the machine and unplug it

→ Safety against interventions in the plate area -

Remove the throat plate completely

→ Check both locks and remove the plate -

Check the underside: Is the plastic nub present?

→ It is usually located centrally or slightly to the side on the underside -

Replace the plate and click it into place

→ Noticeable pressure point and acoustic click -

Clean the sensor area

→ Clean carefully with a brush or compressed air, do not use water - Turn on the machine and check if the detection works

What to do if the plastic nub is missing?

- Buy the original needle plate , as the Nupsi is usually not available separately

- Do not improvise any glue or spare part as this may cause malfunctions

- Temporarily work with sewing function if the embroidery process remains blocked (depending on model)

Tip: Schedule regular visual inspections

Visually check the needle plate each time you insert it for:

- complete plastic parts

- clean sensor areas

- tight fit without play

Summary

If the needle plate isn't recognized, it's usually due to a missing or inactive sensor signal. This is triggered by a small plastic part on the underside of the original needle plate. With a targeted visual inspection and cleaning, the problem can be resolved in just a few minutes.

Split:

Thread salad under the needle plate

Operating instructions Bernette B70 / B79